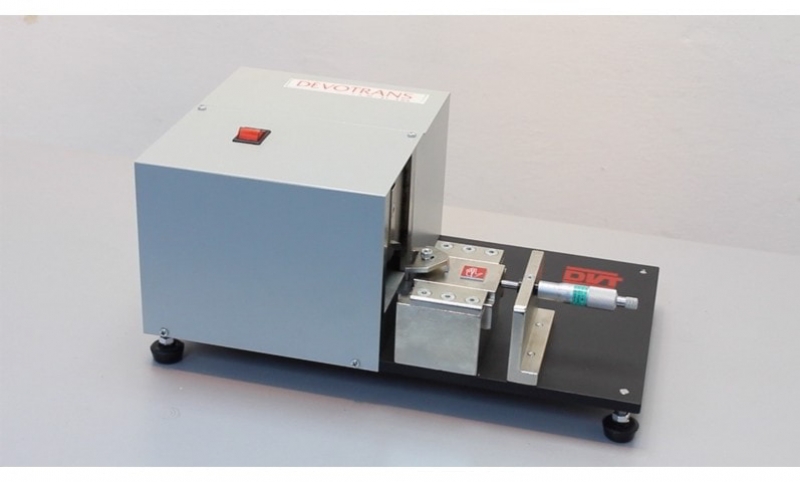

IZOD, CHARPY NOTCH MAKING MACHINE DVT CD A DVT CD A

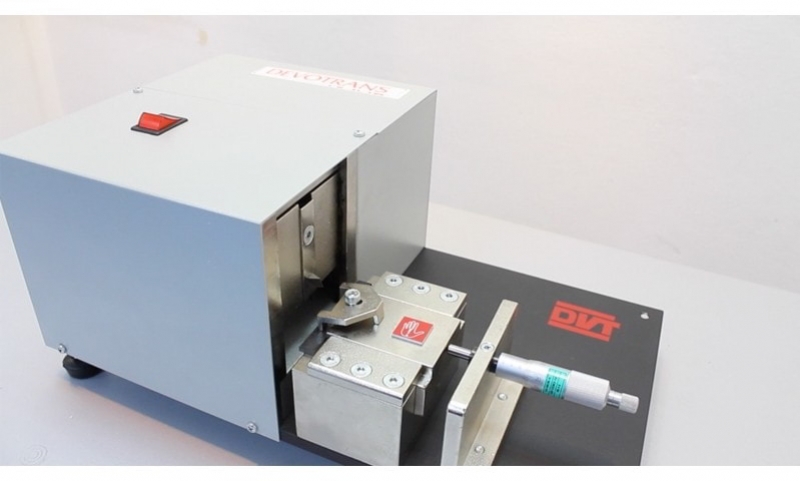

Used to prepare samples for charpy and izod impact tests

INDUSTRIAL SECTORS OF USE

TECHNICAL INFORMATION

- Different forms of radius notches can be machined according to various Standards.

- The notches are at different radius and angles.

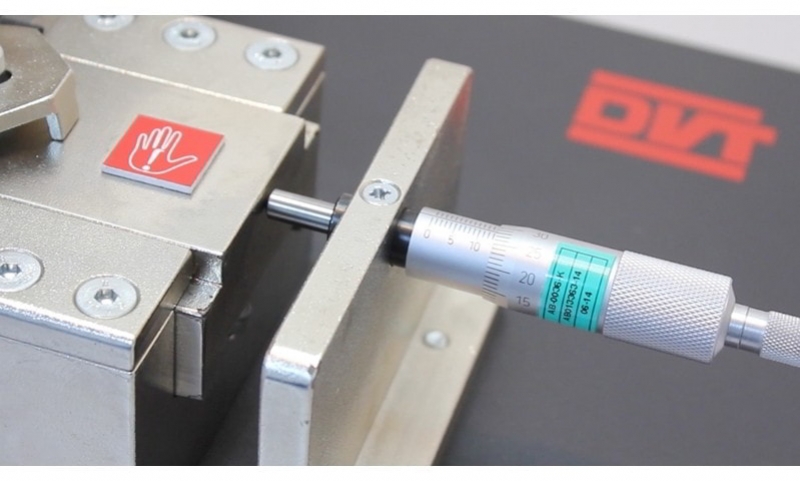

- Micrometer notches at 0.01 sensitivity.

- Continuous machining is possible with electric motors.

- 1 TS EN ISO 179-1 A type notch knife is given together with the machine.

PRODUCTS SUBJECT TO TESTING

- Plastic

OPTIONAL ADDITIONS

- Notch knives for various Standards;

- ISO 180 Type A, Type B

- ISO 179 Type A, Type B, Type C

- Digital micrometer.

- Safety lid.

APPROXIMATE DIMENSIONS AND WEIGHT

- Width : 44 cm.

- Depth: 24 cm.

- Height : 20 cm.

- Weight: 22 Kg.

TECHNICAL DOCUMENTATION

RELEVANT STANDARDS

- ISO 148-3

- ISO 2818

- ASTM 6110

- ISO 8256

- ASTM D 256

- DIN 53453

- TS EN ISO 179-1

- TS EN ISO 180

ADDITIONAL INFORMATION

The IZOD, CHARPY NOTCH MAKING MACHINE enables precise and efficient preparation of notched plastic samples for Charpy and Izod impact tests. It supports various radius and angle configurations in compliance with ISO and ASTM standards, and utilizes a micrometer with 0.01 mm precision for consistent notch formation. Powered by an electric motor, it ensures smooth, continuous operation. Supplied with a TS EN ISO 179-1 A-type notch knife, the machine can be optionally equipped with additional notch knives for ISO 179 and 180, a digital micrometer, and a safety lid. Its compact size and 22 kg weight make it ideal for lab environments requiring standard-compliant testing on plastic materials.