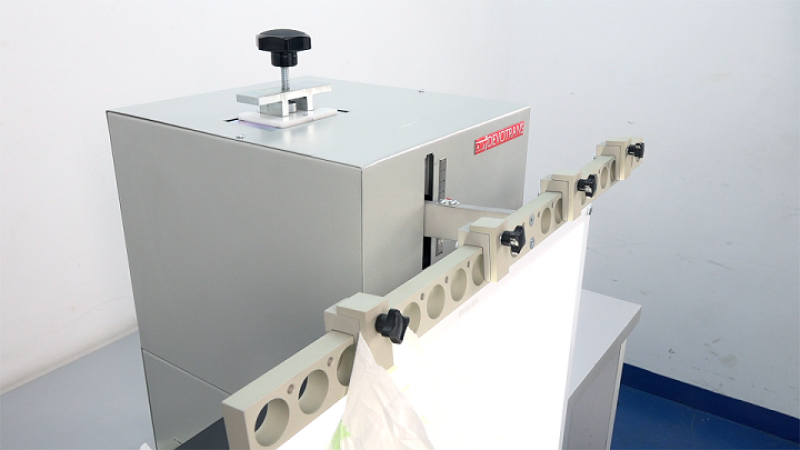

IMPACT TESTER FOR DIAPERS (HIT – HARDY INTEGRITY TESTER) - DVT BBD DVT BBD

Used to observe whether the water absorbents in diapers clump or not when subjected to impact.

Alternative names of tester: hardy integrity tester (HIT tester), core integrity tester, conditioned core cracking tester, baby nappy tester.

INDUSTRIAL SECTORS OF USE

TECHNICAL INFORMATION

- Operating voltage: 220 Volt 50 Hz.

- Test period display.

- Possibility of conducting tests with 4 samples.

- Possibility of changing the position of the sample-holders.

- Emergency stop button.

- Hammer.

- Ruler for adjusting hammer distance.

- Light and sound warning.

- Led light panel.

- Possibility of observing test process with light panel.

- Discrete movement key to make the hammer move slowly.

- Device size allowing the operator to work in sitting or standing position.

INDUSTRIES OF APPLICATION

- Diaper manufacturing.

APPROXIMATE DIMENSIONS AND WEIGHT

- Width: 60 cm.

- Depth: 43 cm.

- Height: 82.5 cm.

- Weight: 34 kg.

ACCESSORIES

- Sample holders (#4).

TECHNICAL DOCUMENTATION

ADDITIONAL INFORMATION

The impact tester for diapers evaluates whether water absorbent materials in diapers form clumps when impacted. It supports testing with 4 samples simultaneously, includes a ruler for adjusting hammer distance, test period display, light and sound warning system, and an emergency stop button. The device operates at 220 Volt 50 Hz and allows visual monitoring via a LED light panel. Sample holder positions are adjustable, and the discrete movement key enables controlled hammer motion. Designed for use in diaper manufacturing.