TEST EQUIPMENT FOR DETERMINATION OF STATIC SLIDING ADHESION IN ADHESIVE BANDS DVT BSK ET DVT BSK ET

Used to test sliding strength of adhesive bands when forces parallel to the adhesion surface and the ground layer are applied. An adhesive band is applied to an appropriate board so that one end remains free within an oven with a temperature range of up to 100° C. The board is mounted in vertical position. Then a standard weight is attached to the free lower end of the adhesive band to measure the time of the band’s sliding adhesion (stripping, splitting).

INDUSTRIAL SECTORS OF USE

TECHNICAL INFORMATION

- Operating voltage: 220 Volt 50 Hz.

- Temperature display.

- Possibility of testing up to 10 samples.

- 10 time displays monitoring the test time for each of the 10 samples.

- Sample cutting apparatuses for cutting samples in accordance with the standards.

- Door and cabin insulation seals made from heat-proof silicon.

- Air circulation system to ensure homogeneous temperature in cabin.

- Temperature range from room temperature +5°C to 100°C.

- High precision temperature control with micro-processor thermostat.

- Stainless steel or aluminium eloxal cabin interior.

- High thermal insulation for savings in operating costs.

- Body coated with electrostatic powder paint.

OPTIONAL ADDITIONS

- Models for room temperature or for high temperatures.

- 5-unit model.

- Rubber tray.

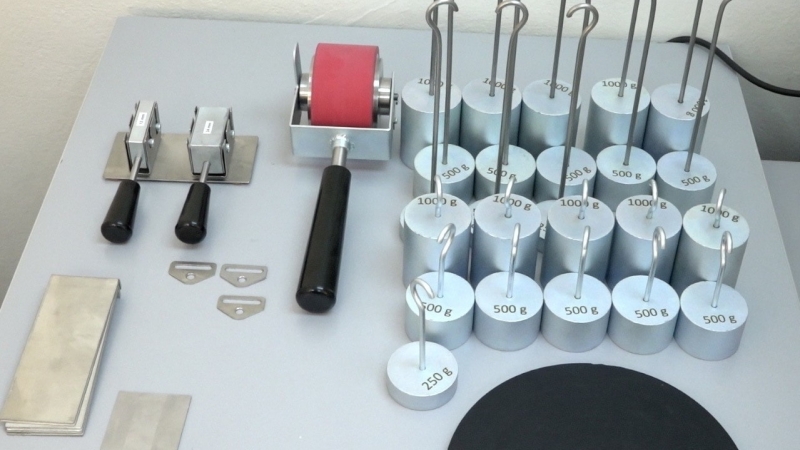

- Sample cutting apparatuses.

- Cylinder.

APPROXIMATE DIMENSIONS AND WEIGHT

- Width: 83 cm.

- Depth: 71 cm.

- Height: 88 cm.

- Weight: 105 kg.

ACCESSORIES

- 150 g weight.

- 500 g weight.

- 1000 g weight.

TECHNICAL DOCUMENTATION

RELEVANT STANDARDS

- TS EN 1943

- EN 1943

- ASTM D 3654

- FCA 9.55368

ADDITIONAL INFORMATION

The test equipment for determining static sliding adhesion in adhesive bands offers reliable performance in evaluating the sliding resistance of adhesive materials under parallel force conditions. With a capacity to test up to 10 samples simultaneously, it features individual time displays for accurate monitoring. The temperature-controlled oven, adjustable from room temperature +5°C to 100°C, ensures homogeneous heating via an air circulation system, while the microprocessor-controlled thermostat maintains precise thermal conditions. Built with stainless steel or aluminium eloxal interiors, heat-resistant silicon seals, and an electrostatic powder-coated body, it provides durability and energy efficiency. The system adheres to TS EN 1943, EN 1943, ASTM D 3654, and FCA 9.55368, and is customizable with optional accessories such as sample cutting tools, weights, rubber trays, and cylinders.