PRODUCT VIDEO WATCH

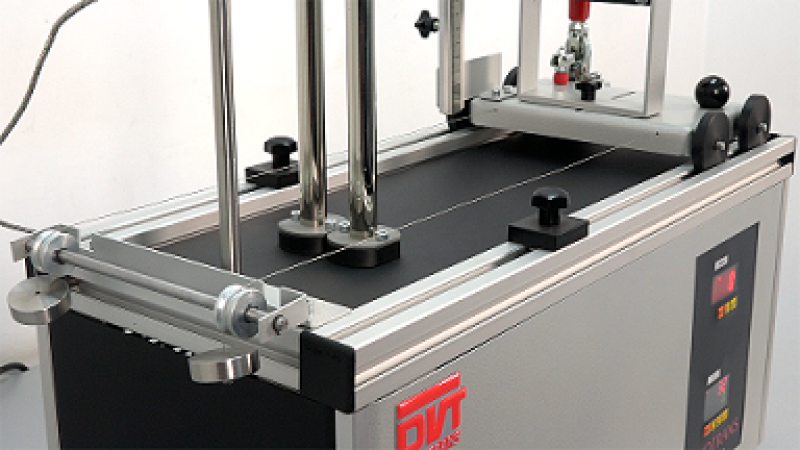

GLOW WIRE TEST EQUIPMENT DVT YAN KTM DVT YAN KTM

Used to observe melting and scorching on plastics subjected to high temperatures caused by high current and to determine whether the sample remains within burning limits.

INDUSTRIAL SECTORS OF USE

TECHNICAL INFORMATION

- Power input: 220 V, 50 Hz.

- Pressure weight: 100 gr.

- Wooden dropping plate.

- Temperature display.

- Current display.

- Temperature setting: 370°C-1000°C.

- High accuracy scale for measuring flame length.

- Holder plate adjustment depending on the sample.

- Control and stabilization system: microprocessor.

- Manually operated

- Heat meter probe

- Electric current setting

INDUSTRIES OF APPLICATION

- Plastics industry.

- Electrical equipment manufacturing.

APPROXIMATE DIMENSIONS AND WEIGHT

- Width: 56 cm

- Depth: 30 cm

- Height: 50 cm

- Weight : 22.7 kg

TECHNICAL DOCUMENTATION

RELEVANT STANDARDS

- TS EN 60695

- IEC 60695

- IEC 60529

- TS EN 60332-1-3 / TS EN 60332-1-1 / TS EN 60332-1-2

- TS EN 61386-1

ADDITIONAL INFORMATION

The glow wire test equipment operates with a 220 V, 50 Hz power input and features temperature setting from 370°C to 1000°C, a 100 gr pressure weight, heat meter probe, electric current setting, microprocessor-based control system, flame length scale, and temperature and current displays. It complies with TS EN 60695, IEC 60695, IEC 60529, TS EN 60332-1-3, TS EN 60332-1-1, TS EN 60332-1-2, TS EN 61386-1 standards and is used in the plastics industry and electrical equipment manufacturing.