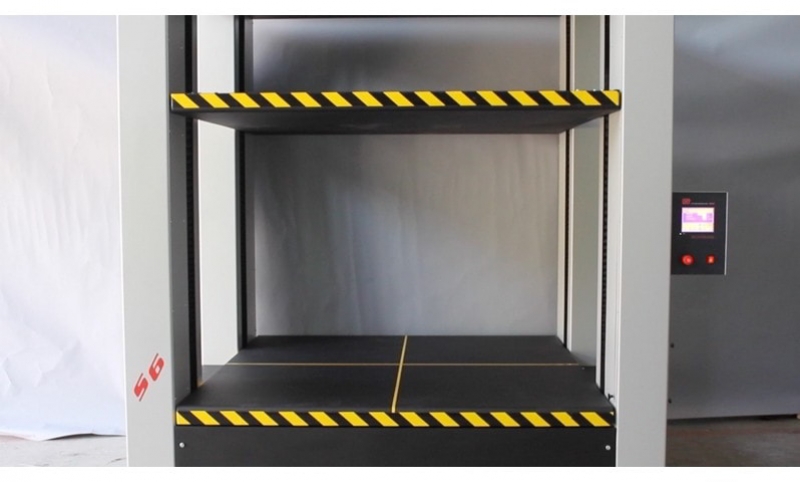

COMPRESSION TESTING MACHINE DVT S6 D NN DVT S6 D NN

Used in fracture, crushing and permanent deformation tests of packaged products under the pressure.

INDUSTRIAL SECTORS OF USE

TECHNICAL INFORMATION

- Operating voltage: 220 VAC, 50 Hz.

- Power consumption: max. 2 KVA.

- Speed adjustment: between 0.100- 500.000 mm/min.

- Colour touch screen.

- Emergency stop button.

- Rapid return to the starting point.

- 2 columns and 2 screw system.

- Maintenance-free, solid and reliable structure.

- Stopping, depending on the Compression/Fracture or distance.

- Movement precision: 0,01 mm.

- Turkish, English, French and Russia language options.

- Force unit: Newton, kN, kg or MPa options.

- Standard software.

TESTS PERFORMED WITH THE DEVICE

- Determination of ring stiffness of pipes, tearing, compression, fracture, stretching, permanent deformation, puncture, transport simulation.

PRODUCTS SUBJECT TO TESTING

- Home appliances.

- Steel, tin cans.

- Plastic case, box, garbage container, pallet.

- Corrugated cardboard boxes.

- Hardboard, wooden boxes.

- Pipes.

OPTIONAL ADDITIONS

- Compression unit can be moved at different angles.

- Different jaw models available

- Special speed control range.

- 0.001 mm motion sensitivity.

- Extensometer.

- Metal or plexiglas safety cage

- Light barrier

APPROXIMATE DIMENSIONS AND WEIGHT

- Width : 170 cm

- Depth : 120 cm

- Height : 190 cm

- Wight : 750 kg

TECHNICAL DOCUMENTATION

RELEVANT STANDARDS

- AFNOR H 13-001

- ASTM D642

- FEFCO 50

- TS EN ISO 12048

- İSTA SERIES

- TAPPI T 804

- DIN EN 22872

- ASTM D 4169

- ASTM D4577

- ASTM D7030

- DIN 55440-1

- 49 CFR 178.606

ADDITIONAL INFORMATION

The Compression Testing Machine offers precise solutions for fracture, crushing, and permanent deformation tests of various packaged products. Operating at 220 VAC with a maximum 2 KVA power consumption, it ensures high precision (0.01 mm) and flexibility through a speed range of 0.100–500.000 mm/min. Equipped with a colour touch screen, emergency stop, and rapid return function, the system features a 2-column and 2-screw structure for durability. Its compatibility with multiple force units (Newton, kN, kg, MPa), multilingual interface, and standard software enables user-friendly operations. Applicable to pipe stiffness, compression, fracture, puncture, and transport simulation tests, it complies with AFNOR, ASTM, ISO, ISTA, TAPPI, and DIN standards. Optional upgrades include 0.001 mm sensitivity, extensometer, safety cage, and movable compression unit, ideal for testing metal, plastic, wood, and cardboard packaging.