PRODUCT VIDEO WATCH

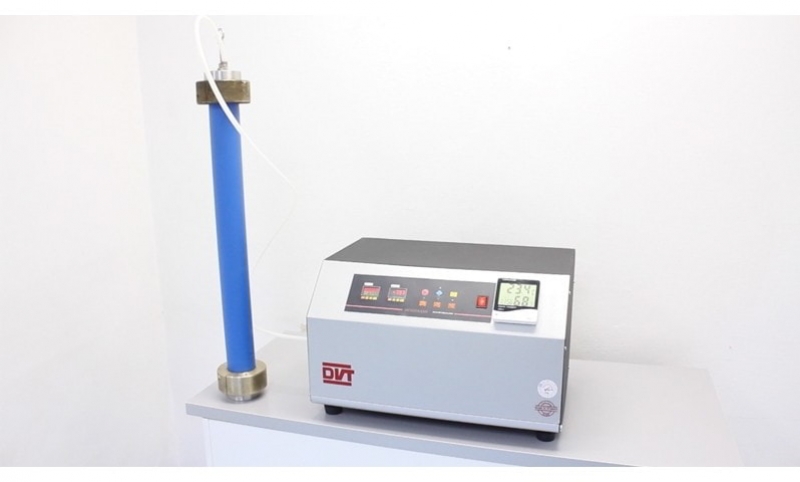

LEAKTIGHTNESS UNDER VACUUM TESTING DVT BBO V DVT BBO V

TECHNICAL INFORMATION

- Manufactured, depending on the different pipe diameters/models and number of tests.

- Vacuum range can be adjusted.

- Test duration is followed up on electronic display.

- Digital and analogue (needle type ) display models are available.

- Materials used is stainless.

- Temperature and humidity displays.

- Time control unit.

APPROXIMATE DIMENSIONS AND WEIGHT

- Width : 51 cm.

- Depth : 66 cm.

- Height : 44 cm.

- Gross weight : 39Kg.

TECHNICAL DOCUMENTATION

RELEVANT STANDARDS

- ISO 13844

- TS EN 12294

- TS EN ISO 13844

ADDITIONAL INFORMATION

The leaktightness under vacuum testing device is essential for verifying the sealing performance of polyethylene and polypropylene pipes and fittings under vacuum. It supports various pipe diameters and models, with adjustable vacuum range and precise monitoring via digital or analogue displays. Made from stainless steel, the unit includes temperature and humidity indicators and a time control unit for reliable and consistent results. Its compact structure (51x66x44 cm) ensures space-efficient setup in testing laboratories. Fully compliant with ISO 13844, TS EN 12294, and TS EN ISO 13844 standards, it is ideal for industrial testing applications.