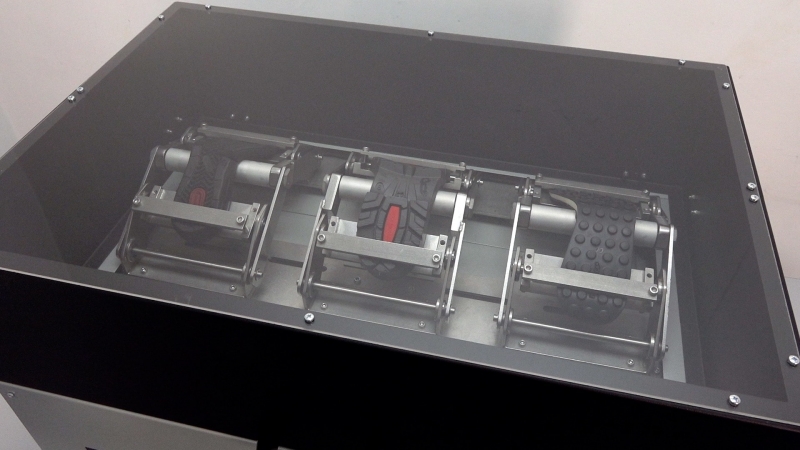

WHOLE SOLE FLEXING TESTER DVT TEM DVT TEM

Used to determine the resistance of material to cut growth during repeated flexing.

The specimen is pierced between the cleats at three points along the line of maximum bending stress. By the specified speed and time of 90° bending action the cuts’ growth are inspected.

INDUSTRIAL SECTORS OF USE

TECHNICAL INFORMATION

- Power drive.

- Manual adjustment.

- Counter up to 999.999.

- 3 samples can be tested at the same time.

- Equipped with an inspection lid.

- Automatic stop in case safety cover is opened.

- Number of flexing presetting.

OPTIONAL ADDITIONS

- Digital thermostat.

- 2nd. safety thermostat

- Special lighting unit.

- Ambient temperature test can be performed.

- Stainless steel body.

- Optional models can be produced.

APPROXIMATE DIMENSIONS AND WEIGHT

- Width : 74 cm.

- Depth : 60 cm.

- Height: 54 cm.

- Weight: 93 Kg.

TECHNICAL DOCUMENTATION

RELEVANT STANDARDS

- ISO 20344

- TS EN ISO 20344

- TS DIN EN 345-2

- DIN EN 344

- EN ISO 17707

ADDITIONAL INFORMATION

The Whole Sole Flexing Tester is designed to assess cut growth resistance of materials such as shoe soles under repeated flexing conditions. With three-point piercing at the maximum bending line and a controlled 90° flexing motion, the device evaluates the material's performance against fatigue. It includes a power drive, manual adjustments, a 999,999 cycle counter, and supports simultaneous testing of 3 specimens. Safety and precision are enhanced with a transparent inspection lid, automatic stop function, and flex count presetting. Optional features like a digital thermostat, additional safety thermostat, and special lighting support varied testing conditions. Built with a stainless steel body, the tester conforms to standards including ISO 20344 and EN ISO 17707, ensuring high reliability for industrial quality control.