FOLDING STRENGTH TESTER FOR ARTIFICIAL LEATHER DVT BUK D DVT BUK D

Used to test the strength of artificial leathers and films against folding from vertical position to either side under a given tensile load.

INDUSTRIAL SECTORS OF USE

TECHNICAL INFORMATION

- Operation voltage: 220 Volt 50 Hz.

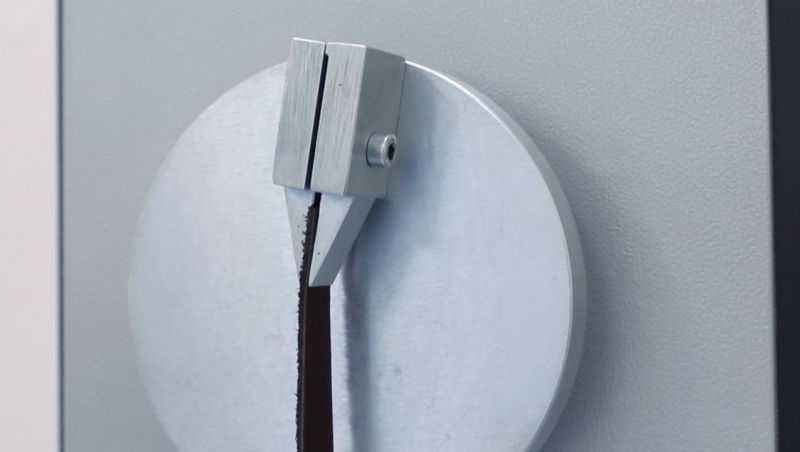

- Sample dimension: 80 mm x 10 mm.

- Possibility of folding sample with lower clamp (fixed) or upper clamp (moving).

- Sample length between jaws: 45 mm.

- Upper clamp moving either side with a 150° angle from vertical.

- Test period counter counting up to 999999 test periods.

- Test speed: 100±5 rpm.

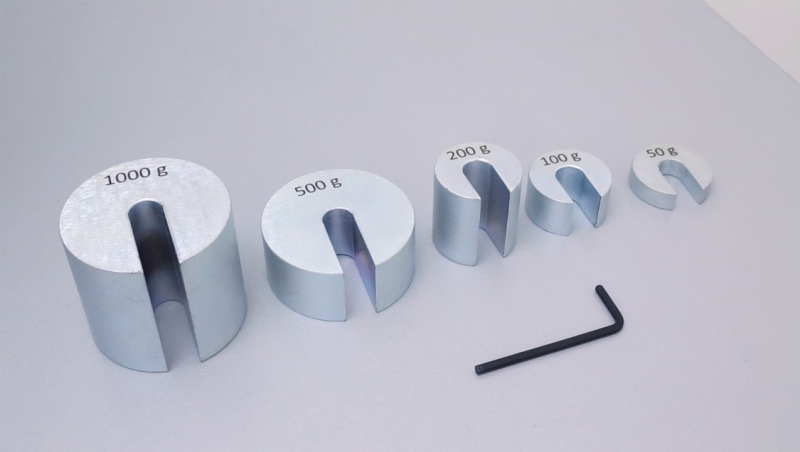

- Additional weights: 50, 100, 200, 500 or 1000 g.

- Sound warning when the test is over.

- Possibility of operating the device at low speed in order to observe the test process.

- Body coated with electrostatic powder paint.

- Maintenance-free robust and reliable structure.

APPROXIMATE DIMENSIONS AND WEIGHT

- Width: 50 cm.

- Depth: 37 cm.

- Height: 58 cm.

- Weight: 18.6 kg.

TECHNICAL DOCUMENTATION

RELEVANT STANDARDS

- GOST 12.4.199-99

- GOST 8978-2003

- ISO 7854-1995

ADDITIONAL INFORMATION

The FOLDING STRENGTH TESTER FOR ARTIFICIAL LEATHER is designed to evaluate the resistance of artificial leather and film samples to repeated folding under tension. With a sample size of 80 mm x 10 mm and a jaw distance of 45 mm, it performs fold cycles at 100±5 rpm with angles of 150° to either side from the vertical. The device accommodates up to 999999 test cycles, offers adjustable weights (50–1000 g), and includes a sound alert upon test completion. Its electrostatic powder-coated body ensures durability, while its maintenance-free structure and low-speed operation mode allow for visual observation during testing. Fully compliant with ISO 7854-1995, GOST 12.4.199-99, and GOST 8978-2003, it’s ideal for quality control and research environments.