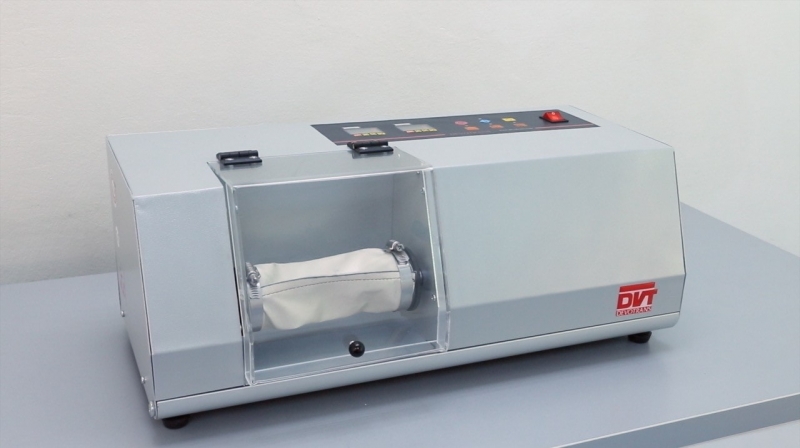

TORSION DAMAGE TESTER DVT BHT DVT BHT

Used to measure the strength of fabrics, leather etc. when they are rucked up and at the same time tightened.

The test is stopped after a given number of period or when the sample exhibit signs of deterioration or cracking.

INDUSTRIAL SECTORS OF USE

TECHNICAL INFORMATION

- Operation voltage: 220 Volt 50 Hz.

- Sample dimensions: 220 mm x 190 mm.

- Bending movement with sample bending disk.

- Compression movement with sample compressing disk.

- Test period counter counts up to 999999 test periods.

- Bending speed: 200 ±10 rpm.

- Compression speed: 152 ±4 rpm.

- Plexiglass protective lid.

- Body coated with electrostatic powder paint.

- Maintenance-free robust and reliable structure.

APPROXIMATE DIMENSIONS AND WEIGHT

- Width: 63 cm.

- Depth: 28 cm.

- Height: 25 cm.

- Weight: 28 kg.

TECHNICAL DOCUMENTATION

RELEVANT STANDARDS

- GOST 12.4.199-99

- GOST 8978-2003

- ISO 7854-1999

ADDITIONAL INFORMATION

The Torsion Damage Tester is designed to evaluate the durability of materials like fabrics and leather under simultaneous rucking and compression stress. Equipped with a bending disk and a compression disk, the device performs precise mechanical actions to simulate wear. With a 220 x 190 mm sample size, 200 ±10 rpm bending speed, and 152 ±4 rpm compression speed, it delivers highly controlled testing conditions. A test period counter supports up to 999999 cycles, ensuring flexibility for long-term endurance studies. The plexiglass protective lid enhances safety, while its electrostatic powder-coated body provides durability. Compliant with ISO 7854-1999, GOST 12.4.199-99, and GOST 8978-2003, this maintenance-free tester is ideal for industrial quality control environments.