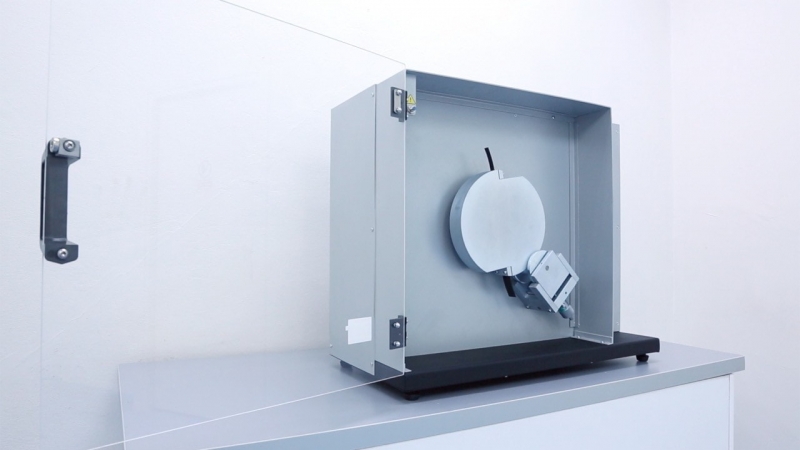

ROTATING FATIGUE TESTER FOR RUBBER DVT DKY DVT DKY

Used to test strength of rubber, plastic etc. soles by the observation of the enlargement of the crack resulting from 90° bending of the sample.

INDUSTRIAL SECTORS OF USE

TECHNICAL INFORMATION

- Operation voltage: 220 Volt 50 Hz.

- Sample dimensions : 68±2 x 10±1 mm or

- 68±2 x 20±1 mm.

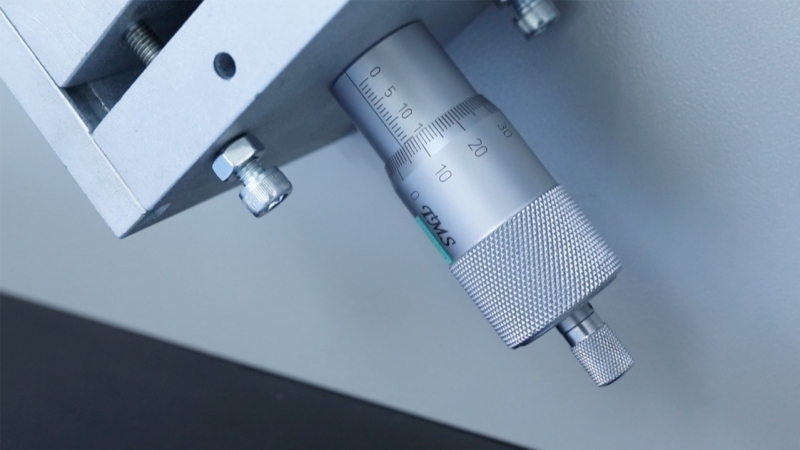

- Micro-metre to measure thickness.

- Micro-metre precision : 0,01 mm.

- Sample folding angle : 90°±2.

- Sample folding with one disk and one pulley.

- Possibility of testing 2 samples simultaneously.

- Test period counter counts up to 999999 revolutions.

- Test speed : 250 ±20 rpm.

- Possibility of operating the device at low speed to observe the test process.

- The device will not operate when protective plexyglass lid is open.

- Emergency stop button.

- Sound warning when test is over.Body coated with electrostatic powder paint.

- Maintenance-free robust and reliable structure.

APPROXIMATE DIMENSIONS AND WEIGHT

- Width: 70 cm.

- Depth: 40 cm.

- Height: 59 cm.

- Weight: 67 kg.

TECHNICAL DOCUMENTATION

RELEVANT STANDARD

- GOST 422-75 (METOD A)

ADDITIONAL INFORMATION

The rotating fatigue tester for rubber is designed to assess the crack propagation resistance of rubber and plastic sole materials under repeated 90°±2 bending stress. It supports simultaneous testing of two samples sized 68±2 x 10±1 mm or 68±2 x 20±1 mm, with thickness precisely measured using a 0.01 mm micro-metre. The device features a test period counter up to 999999 cycles, and a test speed of 250 ±20 rpm, with the option to run at low speeds for visual monitoring. Built for safety, it includes a protective plexiglass lid interlock, emergency stop button, and sound alert upon test completion. Its electrostatic powder-coated body ensures a durable and maintenance-free operation. Fully compliant with GOST 422-75 (Method A), it is ideal for quality control in material testing environments.