TEST EQUIPMENT FOR ENVIRONMENTAL STRESS CRACKING PROGRESSION DVT ESCR DVT ESCR

TECHNICAL INFORMATION

- Operating voltage: 220 Volt 50 Hz.

- Temperature and time display.

- Possibility of testing with 18 samples.

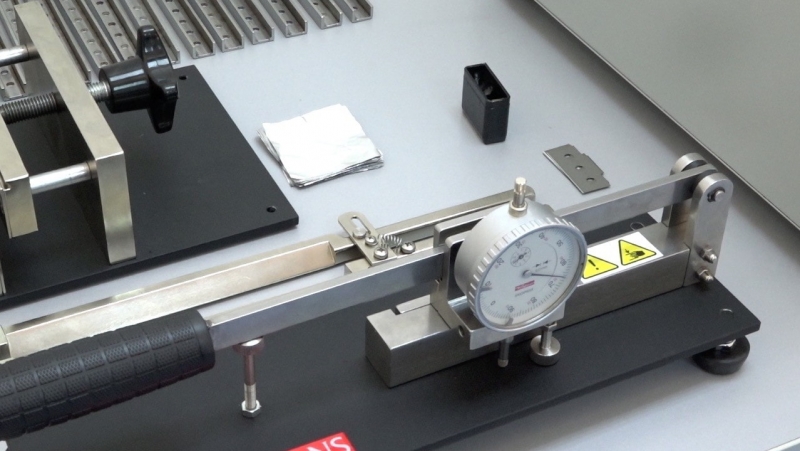

- Notching apparatus.

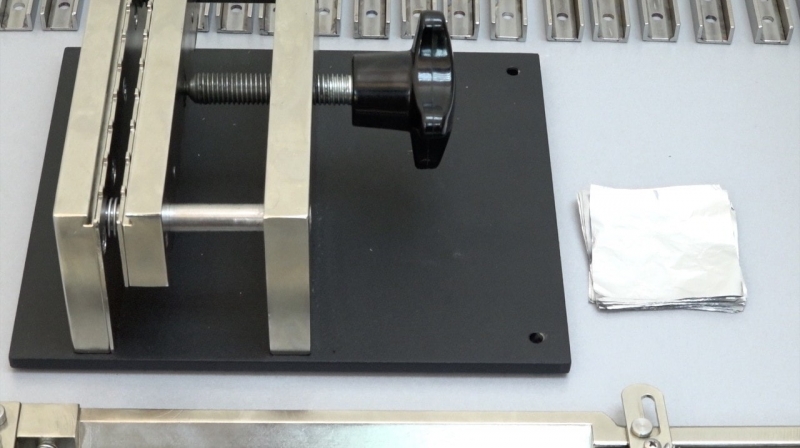

- Sample folding clamp to bend sample.

- Notch comparator to determine notch depth.

- Sample tray.

- Possibility of testing in liquid by adding liquid in vessel.

- Sound and light warning upon expiration of test time.

- High thermal insulation.

- Temperature range from room temperature to 95°C.

- Temperature accuracy: ± 1 % °C.

- Stainless steel inner body.

- Body coated with electrostatic powder paint.

APPROXIMATE DIMENSIONS AND WEIGHT

Together with the apparatuses

- Width: 65 cm.

- Depth: 65 cm.

- Height: 45 cm.

- Weight: 43 kg.

ACCESSORIES

- Notching blade.

- Notching apparatus.

- Sample cutting blade.

- Sample-holding/handling tongs.

- Sample bending apparatus.

- Sample holder.

- Sample rack.

- Glass tube.

- Stopper.

TECHNICAL DOCUMENTATION

RELEVANT STANDARDS

- ASTM D 1693

- TS EN ISO 60811-406

ADDITIONAL INFORMATION

The test equipment for environmental stress cracking progression provides reliable assessment of plastic pipe durability under standardized conditions per ASTM D 1693 and TS EN ISO 60811-406. With the ability to test up to 18 samples simultaneously, it features a precise temperature control range from ambient to 95°C, ±1% °C accuracy, and high thermal insulation for stable test environments. Its stainless steel inner body and electrostatically powder-coated exterior ensure durability and resistance to corrosion. The device includes various accessories such as a notching apparatus, folding clamp, and notch comparator to facilitate sample preparation and measurement. Liquid-based testing is possible within the vessel, and visual/audible alerts notify the operator upon test completion, enhancing operational safety and efficiency.