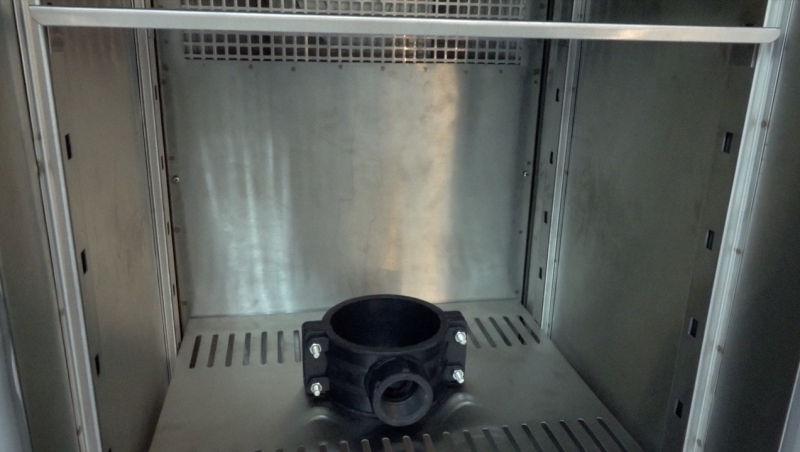

HOT AND COLD TEST EQUIPMENT DVT SSTC DVT SSTC

It is used to test hot and cold environment strength of all kinds of materials.

Two different models with different temperature ranges available, namely: 0°C to +100°C and -10°C to +150°C.

All sectors, including in particular car industry and plastics, rubber and textiles industries.

INDUSTRIAL SECTORS OF USE

TECHNICAL INFORMATION

- Operating voltage: 220 Volt 50 Hz.

- Touch-screen.

- Cable etc. inlet and lid for calibration etc. purposes.

- Air circulation system to ensure homogeneous temperature in cabin.

- Adjustable shelf height.

- Possibility of connecting a USB to the equipment in order to transfer test data in Excel format to a computer.

- Language options: Turkish, English, French and Russian.

- High thermal insulation for savings in operating cost.

- Temperature accuracy: ± 1 % °C.

- Stainless steel inner body.

- Body coated with electrostatic powder paint.

OPTIONAL ADD-ONS

- Glass front side lid.

- Customized dimensions.

- Special apparatuses for in-cabin tests.

- Real-time graphics with computer connection.

- Interior lighting.

APPROXIMATE DIMENSIONS AND WEIGHT

- Width: 97 cm.

- Depth: 91 cm.

- Height: 95 cm.

- Weight: 140 kg.

TECHNICAL DOCUMENTATION

RELEVANT STANDARDS

- TS EN 50525-2-41

- TS EN 1604

- TS EN 60811-100

- TS ISO 6722-1

- TS EN ISO 15874-1

ADDITIONAL INFORMATION

The hot and cold test equipment is designed to evaluate the thermal resistance of materials across various industries, especially automotive, plastics, rubber, and textiles. It is available in two models offering temperature ranges of 0°C to +100°C and -10°C to +150°C, meeting diverse testing needs. With a touch-screen interface, USB data transfer, adjustable shelf height, and air circulation system, it ensures accurate and user-friendly operation. The stainless steel inner body, electrostatically coated exterior, and high thermal insulation contribute to durability and energy efficiency. Compliance with standards such as TS EN 50525-2-41 and TS EN ISO 15874-1 guarantees reliable and standardized performance across testing applications.