TENSILE AND COMPRESSION TEST EQUIPMENT DVT FU50 D NN DVT FU50 D NN

Used for tensile and compression tests on high resistance materials such as metals etc.

INDUSTRIAL SECTORS OF USE

TECHNICAL INFORMATION

- Operating voltage: 220/380 V, 50 Hz, triphased.

- Energy consumption: 7,5 KVA.

- Stopping, depending on the rupture/fracture or distance.

- Maintenance-free, solid and reliable structure.

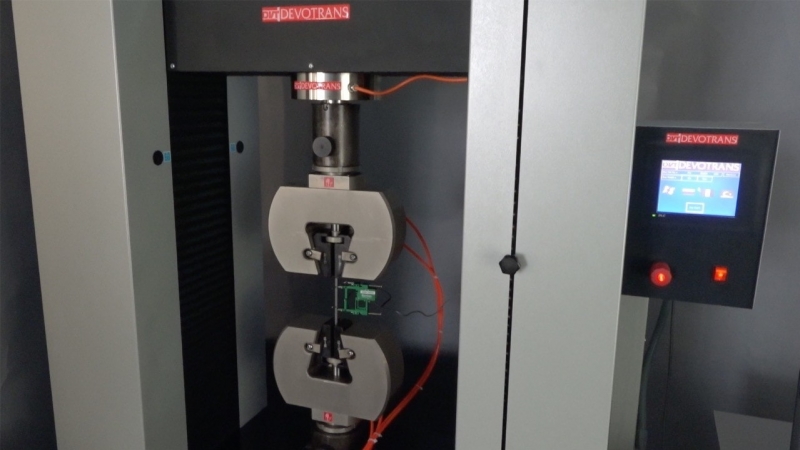

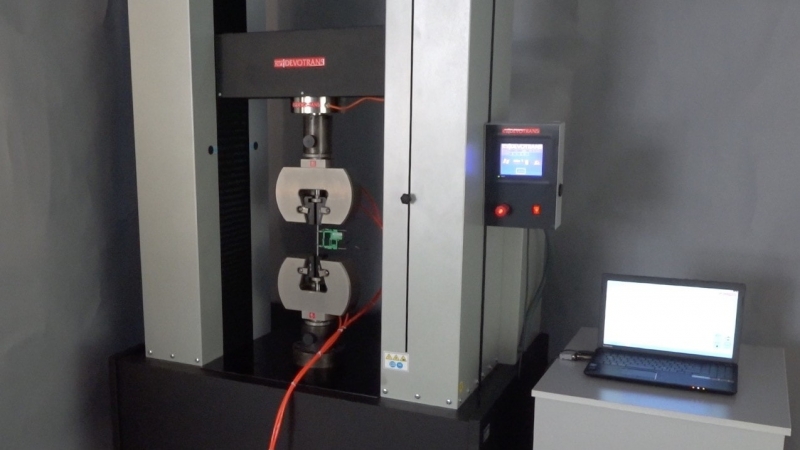

- Touch screen display.

- Rapid return to the starting point.

- Emergency stop button.

- System with 4 columns and 2 screws.

- Capacity: 50 tons (500 kN).

- Precision: ± 0.5%.

- Direction of movement: Upwards in tensile tests.

- Force unit: Newton, Kg or Mpa.

- Range of velocity: 0.002 - 250 mm/min

- Turkish, English, French, Russia language options.

- Computer and printer connection.

TESTS PERFORMED WITH THE DEVICE

- Rupture, elongation, compression, flexion, permanent deformation, puncture tests.

PRODUCTS SUBJECT TO TESTING

- Metals, springs, sheet metal profiles.

- Steel, iron.

- Cables, steel wires.

- Car industry and car industry suppliers.

- Fibre-reinforced composites.

OPTIONAL ADDITIONS

- Specially developed software.

- Different jaw models available.

- Additional devices for special tests.

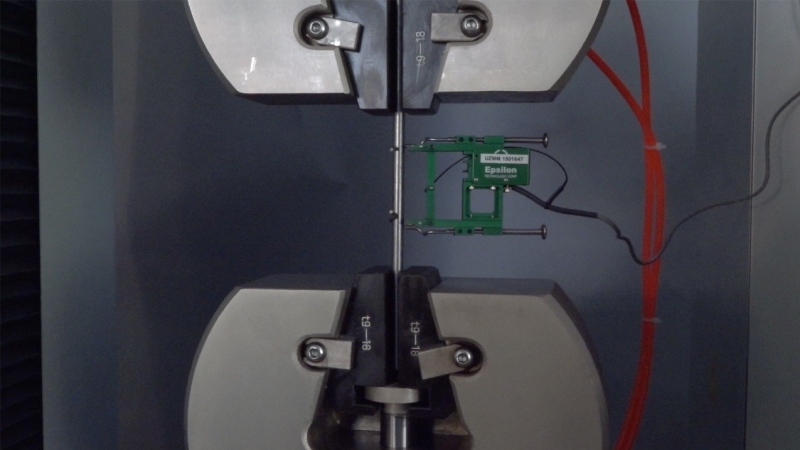

- Extensometer.

- Cubicles for hot and cold environment tests.

- Metal safety cage.

- Range of velocity: 0.002 - 500 mm/min.

APPROXIMATE DIMENSIONS AND WEIGHT

- Width : 142 cm

- Depth : 120 cm

- Height : 265 cm

- Weight : 2555 kg

TECHNICAL DOCUMENTATION

RELEVANT STANDARDS

- TS EN ISO 898-1:2013

- TS EN ISO 7500-1

- TS EN ISO 527-3

- TS EN ISO 6892-1 / 6892-2

- TS 1398-1 EN ISO 527-1

ADDITIONAL INFORMATION

The Tensile and Compression Test Equipment is designed for testing high-resistance materials such as metals, steel, cables, and fibre-reinforced composites under tensile, compression, flexion, deformation, and rupture conditions. With a capacity of 50 tons (500 kN) and ±0.5% precision, it ensures reliable measurements according to TS EN ISO 898-1, ISO 6892, and other key standards. Features like a touch screen, emergency stop, computer connectivity, and multilingual interface enhance operational efficiency and safety. The velocity range of 0.002–500 mm/min allows flexible testing, while optional extensometers, temperature-controlled cubicles, and software upgrades support a wide range of advanced material tests.