IMPACT TEST DEVICE FOR PLASTIC FILM AND PLATE DVT SAH F DVT SAH F

For testing resistance of plastic films and plates to impacts by means of weights provided with the equipment.

INDUSTRIAL SECTORS OF USE

TECHNICAL INFORMATION

- Adjustable pedestals with spirit level.

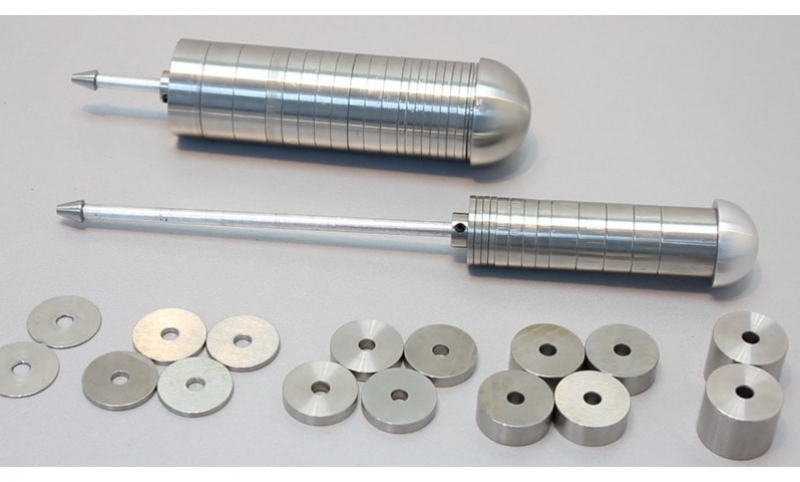

- Provided with 2 sets of test weights.

- Sample dimensions : 200*200 mm.

- Air pressure : 8 bar.

- Led light.

- Drop system with air pedal.

- Sample-holder with air control system.

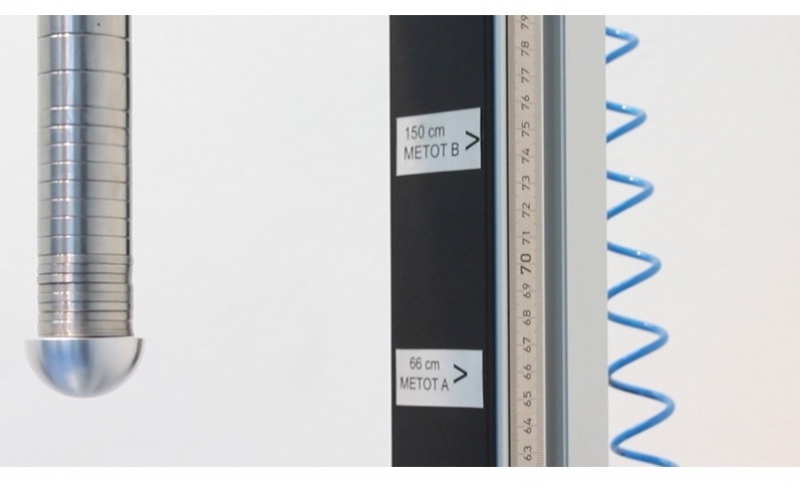

- Height-meter.

- Operating voltage : 220 V 50 Hz.

- Two different impact tips and weight sets complying with the standards.

- Aluminium sphere diameter : 38 mm (Method A)

- Metal sphere diameter : 50 mm (Method B)

- Drop height : 66 cm (Method A) 150 (Method B)

- Foot pedal controlled.

INDUSTRIES OF APPLICATION

- PVC manufacturers.

- Plate manufacturers.

- Manufacturers of packaging films.

- Manufacturers of greenhouse covers.

- Plastic film manufacturers

- Food packaging manufacturers

APPROXIMATE DIMENSIONS AND WEIGHT

- Width : 51 cm.

- Depth : 64 cm.

- Height : 204 cm.

- Weight : 39 kg.

TECHNICAL DOCUMENTATION

RELEVANT STANDARDS

- TS EN ISO 7765-1

- ISO 7765-1

- ASTM D 1709

- GB/9639

ADDITIONAL INFORMATION

The impact test device for plastic film and plate is designed to measure impact resistance using standardized weight sets and interchangeable impact tips. It features an air pedal-controlled drop mechanism, 8 bar air pressure, and a sample-holder with air regulation to ensure repeatability and precision. The 200x200 mm sample size, LED illumination, and integrated height-meter enhance user efficiency. Complying with ISO 7765-1, ASTM D 1709, and other major standards, it supports diverse production lines including PVC, packaging films, and greenhouse cover manufacturing. The dual-sphere system (38 mm aluminum and 50 mm metal) enables flexible testing based on Method A and B requirements.