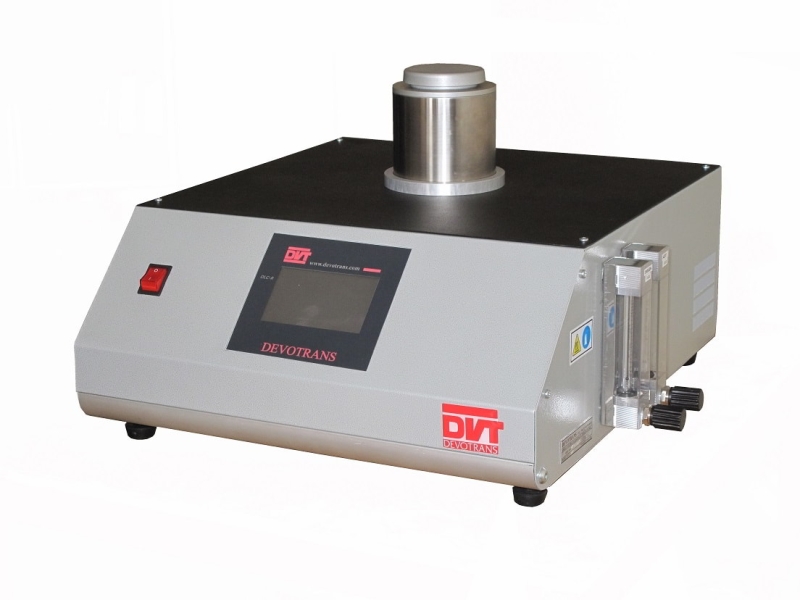

OXIDATION INDUCTION TIME DETERMINATION DEVICE DVT OIT DVT OIT

Used on pipes and fittings. Oxygen is applied to the material under high temperature to create an environment of shock conditioning to observe the time it takes for the material to deteriorate.

INDUSTRIAL SECTORS OF USE

TECHNICAL INFORMATION

- Touch-screen.

- Features of oxygen flow and nitrogen flow.

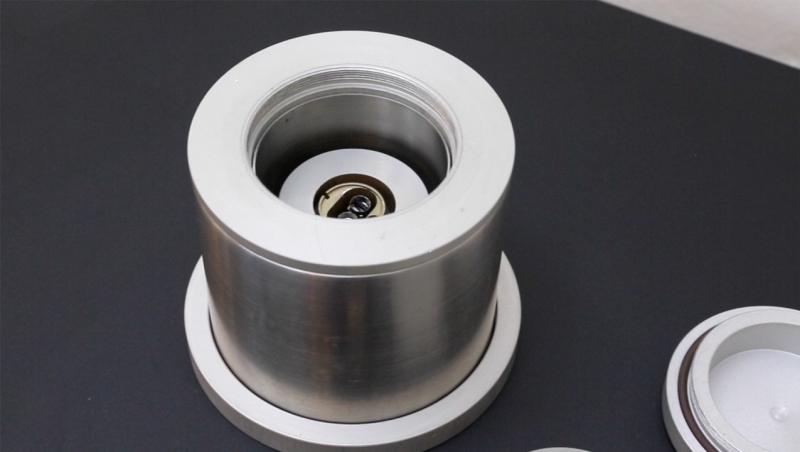

- Compact heating chamber.

- Temperature probe.

- Chronometer.

- PID-controlled temperature sensor.

- Gas-flowmeter setting.

- Software.

- Temperature resolution: 0.1 °C.

- Heating speed: (20±2) °C/min. in the range from 50°C to test temperature.

- Operating voltage: 220VAC, 50 Hz.

- Turkish, English, French and Russian language options.

APPROXIMATE DIMENSIONS AND WEIGHT

- Width: 45 cm.

- Depth: 53 cm.

- Height: 32 cm.

- Weight: 14 kg.

ACCESSORIES

- Sample receptacle/reference receptacle.

- Pair of tongs.

- Spoon.

- Calibration control metal.

TECHNICAL DOCUMENTATION

RELEVANT STANDARDS

- TS EN ISO 11357-6

- EN ISO 11357-6

ADDITIONAL INFORMATION

The Oxidation Induction Time Determination Device is designed for evaluating the thermal oxidation stability of pipes and fittings. It creates a controlled shock conditioning environment using high-temperature oxygen exposure. The device features a PID-controlled temperature sensor, compact heating chamber, and touch-screen interface for precise and user-friendly operation. It supports oxygen and nitrogen flow regulation, has a temperature resolution of 0.1 °C, and operates at a heating rate of (20±2) °C/min from 50°C to the test temperature. Fully compliant with TS EN ISO 11357-6, it includes integrated software for data analysis and offers multilingual support with Turkish, English, French, and Russian options, making it ideal for international applications.