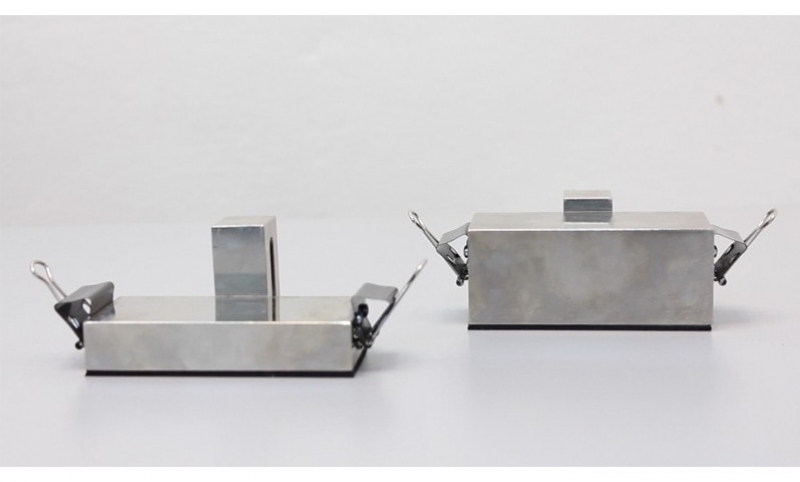

FRICTION TEST DEVICE FOR PRINTED MATERIAL DVT BMS DVT BMS

The device is used to find out the amount of scratching that occurs on wet or dry printed materials as a result of friction.

INDUSTRIAL SECTORS OF USE

TECHNICAL INFORMATION

- Speed of friction can be set

- Possibility to chose from different friction lengths

- Test period counter

- Various pressure forces can be applied

- Tests in wet or dry environment

- 1 sample station

- Pressure weight: 900 gr. and 1800 gr.

INDUSTRIES OF APPLICATION

- Printing houses

- Label manufacturers

- Non-woven manufacturers

- Textile/ready-made garment printing facilities

PRODUCTS SUBJECT TO TESTING

- Paper

- Packaging

- Corrugated paper

- Folded cardboard

- Labels on packaging

- Products with a printed surface

OPTIONAL ADDITIONS

- Different weights

APPROXIMATE DIMENSIONS AND WEIGHT

- Width: 35 cm.

- Depth: 45 cm.

- Height: 23 cm.

- Weight: 25 Kg.

DOCUMENTS

RELEVANT STANDARD

- ASTM D-5264

ADDITIONAL INFORMATION

The friction test device for printed material is designed for precise evaluation of scratch resistance under both wet and dry conditions, aligning with ASTM D-5264 standards. It offers adjustable friction speed, selectable friction lengths, and variable pressure forces to simulate real-world handling. Equipped with a test period counter and a single sample station, it ensures consistent and repeatable testing. 900 gr and 1800 gr pressure weights allow for customizable force application. Widely used in printing houses, label and packaging manufacturing, and textile printing industries, it effectively tests paper, corrugated board, folded cartons, and printed labels for durability against frictional wear.