TEST SOFTWARE DVT CKSIII DVT CKSIII

The CKS-III software program communicates with DVT DEVOTRANS tensile – compression test machines through the TCP/IP protocol to analyse the data obtained during the test in accordance with the relevant standards and to report the test results.

The CKS-III software program can be used by the customers for more specific tests such as 3-point flexural and 4-point bending, fatigue, rigidity, creep, constant load increase tests as well as for basic tests such as tensile, compression, tearing, peeling tests.

In addition to the basic tests, there are other various tests under these categories as described in the relevant standards.

USED IN

Technical information

- Number of samples that can be tested consecutively: 1 to 50.

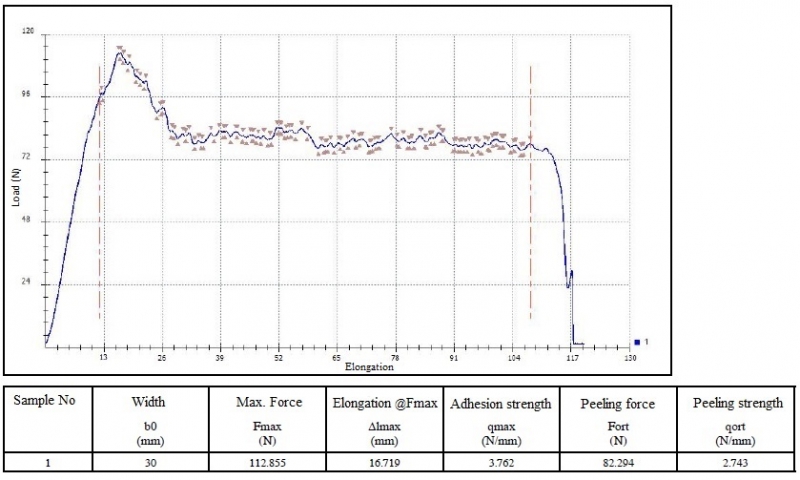

- Graphic screen displaying as many test curves as samples tested.

- Test results tab showing test results for each sample line by line.

- Test results tab showing averages, standard deviations and %Cv calculations for test results.

- Possibility of defining different users and limiting authorizations of users in the software program.

- Possibility of archiving test results (data backup).

- Possibility of inserting corporate letterhead and logo in report page.

- Possibility of inserting sample photograph in lower right corner of report page.

- Possibility of using network printers to obtain report printouts in pdf format.

- Possibility of transferring report printouts to Excel.

- Possibility of changing report title.

- Possibility of resetting with one keystroke force elongation extensometer elongation values simultaneously.

- Automatic return after test.

- Possibility of retrieving and resuming a previous test.

- Possibility of converting units after test

- Available units are: gf, kgf, N, kN, lb for force; N/mm², kPa, Mpa for stress; mm, cm, dm, m, inch or % for elongation.

- Individual curves for each unit.

- Detail test results such as e-modulus, yield point, %0.2 point, max. force, breaking strength, max. extensometer elongation etc.

- Possibility of observing progress of test during test.

- Possibility of transferring instantaneous test data such as force, stress, elongation etc. to Excel.

- Possibility of selecting and displaying specific results from among the test results prescribed by the standard depending on the test type.

- Possibility of obtaining test results in the form of report printouts.

- Language options available for the test software program are: Turkish, English, French, Russian and Italian.

Test Types

1- Tensile tests

Tensile tests are used to determine the tensile characteristics of the sample by applying to it a tensile force with a given distance or load. In addition, these tests allow one to determine the creep behaviour, maximum strength, breaking strength, breaking elongation, breaking force or, additionally, for elastic materials, yield stress and elastic modulus of the sample.

Examples of tests:

- a) Tensile properties determination test

- b) Rupture strength test

- c) Mechanical properties of fasteners for metals

- d) Tensile according to force (f), tensile according to distance (d)

- e) Test for the determination of physical features of yarns

- f) Step-by-step tensile (depending on the force f, depending on the distance d)

- g) Fixed seam opening method

- h) Ductility test

- i) Tensile creep test – Tensile according to force (f)

- j) Co-efficient friction determination test

- k) Rupture at peak test

2- Tearing/peeling tests

Tearing and peeling tests are used to determine the resistance against tearing and to measure the strength of adhesion against peeling.

Examples of tests:

- a) Tearing strength test

- b) Peeling strength test

3- Compression tests

Compression tests are used to determine the compression characteristics of the sample by applying to it a compression force with a given distance or load. In addition, these tests allow one to determine a number of parameters such as the maximum strength, the fracture resistance, the fracture distance variation, the fracture force or, additionally, for elastic materials, yield stress and elastic modulus, by applying to the sample a force in the direction of compression in a process that lasts until the point of fracture.

Examples of tests:

- a) 3 point flexural test

- b) Compression/fracture test

- c) Compression test (depending on the force f, depending on the distance d)

- d) Energy absorption determination test

- e) Step-by-step compression (depending on the force f, depending on the distance d)

- f) Creep test (waiting under a constant load test) – with the 3-point bending method (f in accordance with the force)

- g) Creep test (waiting under a constant load test) – in the direction of compression (f in accordance with the force)

4- Ring stiffness tests

Ring stiffness tests are used to determine creep, ring elasticity and ring stiffness for plastic pipes and ring deformation value for spiral-wound plastic pipes and fittings.

Examples of tests:

- a) Determination of ring stiffness

- b) Pipe creep test

- c) Ring shape change test

- d) Determination of ring flexibility

5- Hysteresis tests

Hysteresis tests consist of subjecting a material to repeated loadings. After various loading and unloading movements, the loss of energy that has occurred in the material is measured at the end of the test. It allows one to determine the loss of force resulting from repetitive tensile – compression operations within a restricted distance of movement.

Examples of tests:

- a) Effort test (depending on the distance d)

- b) Fatigue hysteresis test (depending on the force f)

- c) Fatigue hysteresis test (depending on the distance d)

- d) Hardness test (depending on the force f)

- e) Radial loading test

- f) Cycled hysteresis test

- g) Determination of the elasticity of fabrics

- h) Stepped hysteresis test (depending on the force f)

- i) Stepped hysteresis test (depending on the distance d)

6- 4-point bending,-tensile-compression tests

4-point bending-tensile-compression tests are used to measure the final load carried by the sample that migrates under the effect of slipping to calculate the slip modulus from the load – deflection curve. To explore the bending behaviour of samples, features such as resistance to bending, bending modulus and bending stress/size variation relation are determined.

Examples of tests:

- a) 4-point bending test

- b) Traction strength test

- c) Compression strength test

- d) 4-point wrinkling test

- e) Determination of the creep coefficient test

- f) 4-point bending strength determination test for glass

7- Paper, cardboard tests

Find below descriptions of tests conducted with paper, cardboard samples:

- a) Tensile properties determination test

- b) Rupture strength test - Wet/Dry

- c) Box crush test

- d) Determination of crush resistance

Examples of tests conducted for determination of crush resistance:

- Corrugation profile crush resistance determination test (CCT): used to determine surface crush resistance of corrugation profiles.

- Surface crush resistance determination test (CMT): the two methods used for the determination of the surface crush resistance of corrugation profiles.

- Edgewise crush resistance of corrugated cardboard determination test (ECT): Compression plate surfaces are used to determine vertical crush resistance of corrugated cardboards and corrugation profiles.

- Surface crush resistance determination test (FCT): allows one to determine surface crush resistance of corrugated cardboards used in the manufacturing of transportation packaging. This test can be applied to single-face and double-face corrugated fibreboards.

- Puncture test (LPET): used to determine measurement of energy consumed during puncture operation conducted on corrugated cardboard.

- Adhesion test for cardboard corrugation profiles (PAT): allows one to determine resistance to detachment of adhesion lines of cardboard corrugation profiles.

- Ring resistance to crushing determination test for paper (RCT): used to determine ring resistance to crushing of cardboard or paper.

8- Constant-Rate-of-Loading (CRL) Tests

- a) Tensile (depending on the force f, depending on the distance d)

- b) Compression test (depending on the force f, depending on the distance d)

- c) 3-point flexural test